There are few sounds worse than that of a wheel scraping the kerb. It can make your heart sink, send shivers down your spine and even make you question your aptitude for driving. Unfortunately, it’s all too easy to do. Wheels keep getting bigger and more prone to damage, and even if you tiptoe around the many hazards on our roads, the environment, heat and brake dust are slowly eating away at the finish.

So, what are your options? Replacing wheels isn’t cheap – easily stretching into several lakhs for the larger wheels on premium cars. Refurbishment is the better bet, then, and we looked up SK AutoSmart, which is trying to offer refurbishments through a partnership with DCR (Diamond Cut Refinishing) Systems that has been in the business of manufacturing alloy wheel refinishing equipment in the UK since 2011. SK AutoSmart is now bringing these machines to India with plans to build a nationwide network of franchise partners.

We visited their flagship facility in Mumbai to learn how wheels are refurbished from Matt Corby, head of technical operations. We used a 16-inch wheel from a Hyundai Venue for our test, but the equipment can accommodate wheels up to 24 inches with the tyre in place and 30 inches with the tyre removed. The system largely comprises three separate machines – the first for prep, the second for diamond cutting and the third for painting and curing.

The process starts with the H2O Wet Blaster. Once this booth is sealed, the operator inserts his hands through two integrated rubber gloves and uses a nozzle to blast the wheel with a mixture of water and an abrasive media. Ten minutes is all it takes for any dirt or corrosion to be stripped off the wheel and surface to be keyed in preparation for paint. At this point, any scratches on the wheel spokes can be filled in using a wheel-specific filler before moving on to paint. However, if the wheel has a diamond-cut finish or if the customer wants to add it, the wheel moves on to a diamond-cutting machine.

Here, the wheel is mounted securely to an assembly that rotates while a diamond-coated tip skims the wheel face for the diamond finish. The process is almost entirely automated, starting with a buckle test to ensure the wheel isn’t bent. The operator then marks specific points on the wheel face that will be cut, and the machine gets to work. Each pass takes around 30 seconds, and Matt recommends skimming just 0.2mm each time – taking off metal is a lot easier than adding it back on, as he rightly says. Within a couple of passes, the kerb marks on our wheel totally disappear, and it is time for a coat of lacquer.

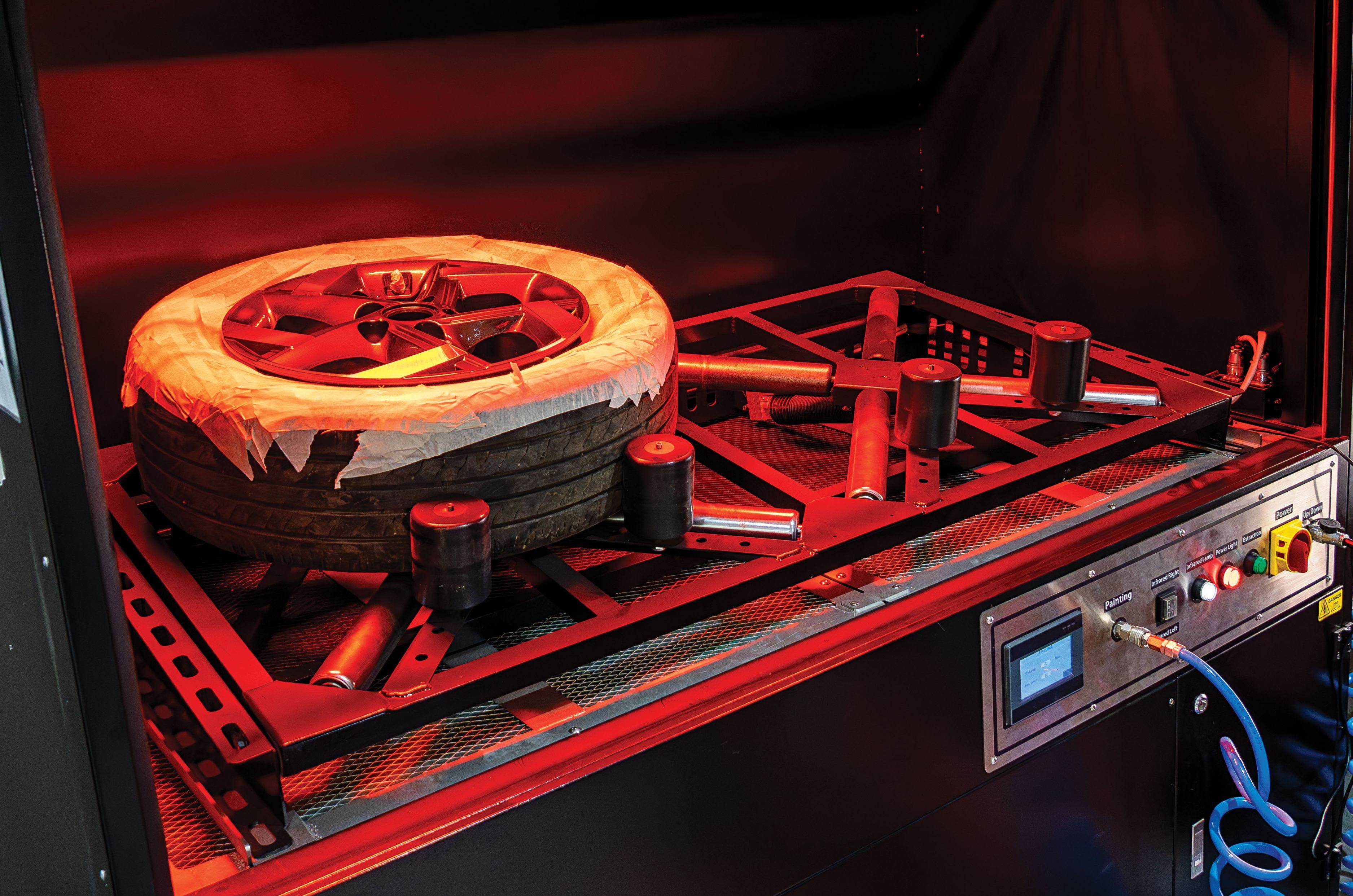

For this, the wheel moves to the Spray and Cure booth, which can electrically lift and rotate the wheel so that it can be painted evenly. The wheel can be painted in any shade you choose, but since we are going for an OEM finish, a clear coat of lacquer is applied using the integrated spray gun. Next, the booth is sealed, and an infrared light cures the paint in an impressive 20 minutes. From start to finish, each wheel spends around an hour in the machines, which means a car can be in and out of the shop in around 5 hours.

Of course, there are limitations – if a scratch is deeper than 2mm or if the wheel is buckled or cracked in any way, the DCR systems can’t help you. Matt says that while others may undertake that type of repair, he finds replacement to be the safer option in such cases. However, when it comes to cosmetic repairs, the finish achievable at SK AutoSmart is superb, especially when you consider the cost. While exact pricing varies depending on the size of the wheel and the extent of the damage, prices currently start at around Rs 7,000 per corner – great value when you consider that on larger rims, this can be just 10 per cent of the total cost of a replacement.

Also see:

How tyre brands are getting a grip on sustainability